Ceramic Shot Peening

Key words:

Ceramic Shot Peening

Classification:

- Product Description

-

Chemical composition (%)

Code

Chemical composition (%)

ZrO2+HfO2

SiO2

Al2O3

ZSQ

60-70

20-30

≤10

Physical performance parameters

True density (g/cm3)

Bulk density (g/cm3)

Vickers hardness HV1

3.85

>2.30

700

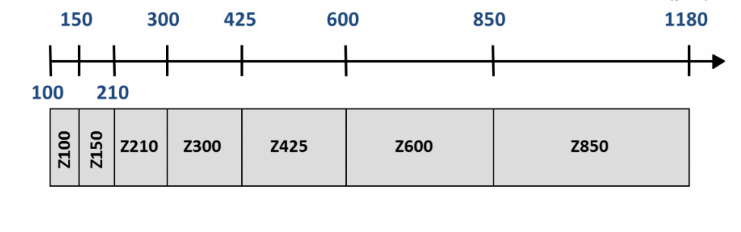

Product particle size (μm)

Main applications

Has always been the industrial standard for ceramic media, used as an industrial benchmark medium for ceramic shot peening, which can enhance the fatigue resistance of mechanical parts made of metal alloys such as hard steel, titanium, and aluminum. In shot peening forming, Zirshot can also be used for the forming and straightening of slender hard alloys in aerospace structural components.

Previous Ceramic blasting beads

Next Zirconia based thermal spray powders (ZrO₂/Y₂O₃, ZrO₂/CaO,ZrO₂/MgO,Gd₂O₃/ZrO₂,ZrO₂/Y₂O₃-Yb₂O₃-Gd₂O₃)

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Contact Phone:

Focus on us

Online message

We will contact you within one working day. Please pay attention to your email.