Ceramic blasting beads

Key words:

Ceramic blasting beads

Classification:

- Product Description

-

Chemical Composition (%)

Code

Chemical Composition (%)

ZrO2+HfO2

SiO2

Al2O3

ZSQ

60-70

20-30

≤10

Physical Performance Parameters

True Density (g/cm3)

Bulk Density (g/cm3)

Vickers Hardness HV1

3.85

>2.30

700

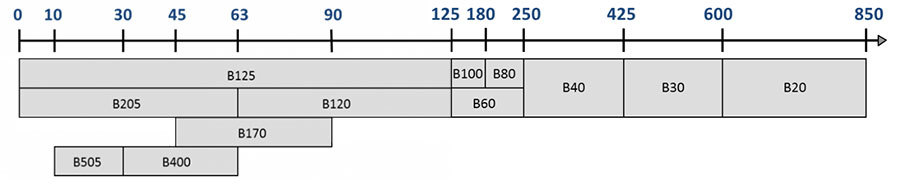

Product Granularity

Main Applications

The product is mainly used for sandblasting cleaning, surface pretreatment, surface finishing, and shot peening of materials such as high carbon steel, stainless steel, aluminum alloy, titanium alloy, magnesium alloy, brass, copper alloy, and plastics. For example, the B20 to B60 series coarse ceramic sand is mainly used for sandblasting cleaning of various industrial components such as molds, engine parts, turbine machinery parts, welded steel parts, and forged and cast metals. The B120 to B205 series fine ceramic beads are mainly used for very smooth polishing of stainless steel, aluminum, titanium, magnesium, and even plastic surfaces, producing a unique satin finish, and can also provide aesthetically pleasing high-quality components for various application fields such as automotive, aerospace, electronics, home appliances, sports goods, and construction.

Previous Fused yttria stabilized zirconia / ytterbium stabilized zirconia

Next Ceramic Shot Peening

Related Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Contact Phone:

Focus on us

Online message

We will contact you within one working day. Please pay attention to your email.